IIT Kanpur Startup’s Eco-Friendly Thermocol Can Double Up As Fertiliser

Founder of IIT Kanpur-incubated startup Kinoko Biotech, Chaitanya Dubey has developed a biodegradable thermocol that also serves as a fertiliser.

One aspect in which most Indian households excel is the art of stockpiling items for future use. Our storerooms often house peculiar items like old cardboard boxes and abundant thermocol sheets.

Whether it’s for parties, school projects, or packaging needs, thermocol frequently assumes the role of an essential guest. Its robustness, widespread availability, and lightweight nature make it suitable for various purposes, contributing to its popularity.

However, amidst its seemingly versatile applications, we tend to overlook its environmental impact. While much attention is given to the detrimental effects of plastic on the planet, there is a less-discussed culprit — polystyrene. As thermocol is composed of polystyrene, it becomes non-biodegradable and, when exposed to sunlight, produces harmful air pollutants.

The thermocol utilised in households and the expansive packaging industry often ends up filling landfills, eventually finding its way to the sea. Research indicates that burning thermocol, a practice prevalent in many households, releases not only Carbon Monoxide but also Styrene and a variety of other toxic chemical compounds, leading to a myriad of eye and lung infections.

Despite numerous studies highlighting the adverse effects of thermocol, its widespread usage continues to escalate. This raises a pivotal question: is there a comparatively effective alternative for the packaging industry?

A 29-year-old engineer Chaitanya Dubey from Kanpur, Uttar Pradesh, may hold the solution to this issue. This young entrepreneur has successfully created a biodegradable alternative to traditional thermocol using mushroom mycelium and agricultural waste.

“Once its intended purpose is fulfilled, just crush it and integrate it into your plants — it will serve as a natural fertiliser for them,” he explains to The Better India.

Chaitanya’s journey began almost four years ago when he had just graduated from college and was exploring new ideas to pursue. Let’s take a look at how this biodegradable solution came to be.

Bringing a sustainable alternative

Born and raised in Kanpur, Chaitanya grew up in a business-oriented family. “While my father was a businessman, I never really thought I would be one. Like most families, my parents wanted me to pursue engineering and secure a job,” he reflects.

The predetermined path seemed reasonable, and Chaitanya pursued his engineering degree in Bengaluru. “After completing engineering, the next step is typically to work or pursue an MBA. That was my plan too. I started working at a company in Bengaluru while contemplating the idea of getting an MBA,” he shares.

However, his plans took an unexpected turn when he enrolled in a small business course in Solan. “It was a brief course that, in many ways, altered my trajectory and led me to where I am today. The course opened up various career possibilities for me, and I could envision myself as an entrepreneur. It was during this course that I was introduced to mushroom farming and its potential for generating significant profits,” he explains.

Mushroom farming marked the initial step that eventually led Chaitanya to his innovative breakthrough. “I initiated a small business where I cultivated both medicinal and commercial mushrooms. While it was progressing well, I aspired to do more,” he recollects.

This desire prompted Chaitanya to delve into researching the diverse uses of different parts of mushrooms. During this exploration, he discovered the emerging concept of creating leather from mushrooms.

“Although it was primarily a circulating concept at the time, it steered me towards questioning what else could be crafted using mushrooms,” he reflects.

To further his research, he also reached out to IIT-Kanpur. “It was a gradual transition and we still grow and sell mushrooms. It was after months of research and development that I was able to make it,” he says.

In 2019, he incorporated his company under the name Kinoko Biotech — an agri-tech company that makes biomaterials out of mushrooms.

Sturdy, lightweight and planet-friendly

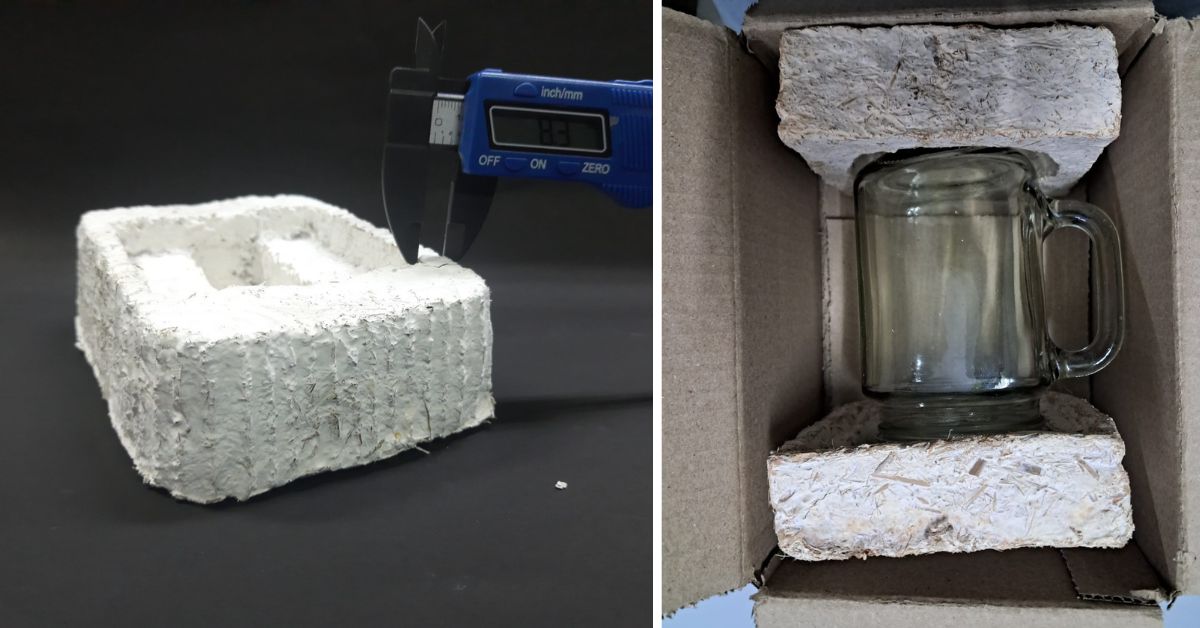

The thermocol is lightweight, sturdy and has the same feel as the polystyrene. “In terms of strength, it compares favourably to high-density thermocol; however, weight-wise, it leans a bit on the heavier side,” he informs.

Discussing the elements used to create the eco-friendly alternative, he explains, “Mycelium, or the roots of the mushroom, serves as a natural adhesive. Additionally, we utilise a combination of agricultural waste and natural fibres, contributing to the durability and longevity of the thermocol. The inherent properties of mushrooms make for a robust material.”

He continues, “Since these are technically made out of roots of the mushroom, they become a byproduct of mushroom and a subcategory. Made of natural materials, the thermocol starts to decompose in about 60 to 90 days. Besides throwing it away, one can actually use it as a nourisher and natural fertiliser for plants.”

The thermocol takes about five to seven days to be made. “When it comes to thermocol, there exists a wide range of varieties. Our product falls on the slightly higher cost spectrum compared to low-density thermocol but remains more affordable than high-density thermocol,” he says.

“To put it into perspective, our pricing falls in the mid-range, around Rs 20 to Rs 25 for 100g of packaging. In comparison, low-density thermocol typically ranges from Rs 15 to Rs 20, while high-density thermocol can vary widely, reaching anywhere from Rs 30 to Rs 100 or more,” he says.

The product is presently accessible for packaging businesses, but Chaitanya has ambitious plans to expand production and make it available for the general public as well.

“We are also in the process of developing a material using mushrooms to create idols. Many alternatives to POP (Plaster of Paris) are harmful to the environment. Currently, our plant capacity allows for the production of 200 pieces of thermocol a day, but as part of our future plans, we aim to increase this to 1,000 pieces per day,” he explains.

Being a newcomer in the market, Chaitanya is navigating the intricacies of supply chain management and persuading businesses to make this eco-friendly switch.

“While most people have some awareness of the environmental impact of polystyrene thermocol, there aren’t many substitutes available in the market. With my green innovation, I hope to provide them with an alternative and an opportunity to contribute positively to the environment,” he expresses.

(Edited by Padmashree Pande)

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let's ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?